TECHNICAL EXPERTISE – SERVICE EXCELLENCE – MANUFACTURING EXPERIENCE

For over half a century, Precision Associates has been a leading manufacturer of top quality, custom rubber seals and other rubber products for a variety of markets.

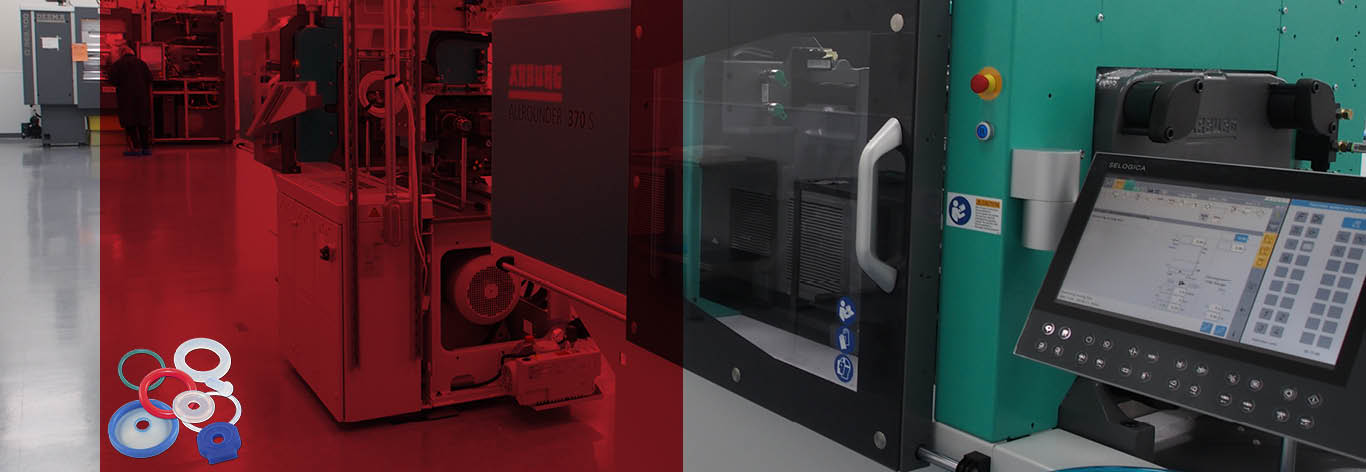

Leveraging our expertise in medical device component manufacturing, we’ve expanded our capabilities to include liquid silicone rubber (LSR) molding in our newly expanded Class 7 clean room which now totals 13,000 square feet.

We offer engineering services from initial part analysis to final delivery. With an onsite tool shop, we can provide prototypes quickly and economically. From your drawing, 3D model or sample parts, our engineers can review the manufacturability of the part and recommend changes that will reduce costs without compromising performance. Our research and development (R&D) laboratory can recommend materials suited for your application and offer testing methods and services you may need to prove performance characteristics.

PAI specializes in homogeneous thermoset rubber, liquid silicone rubber and rubber bonded-to-metal or plastic inserts. Our manufacturing capabilities include product sizes from 36 inches to micro-miniature parts in a variety of standard

and custom sealing profiles.